Mechanical Breakdown When Moving Parts Stop Moving

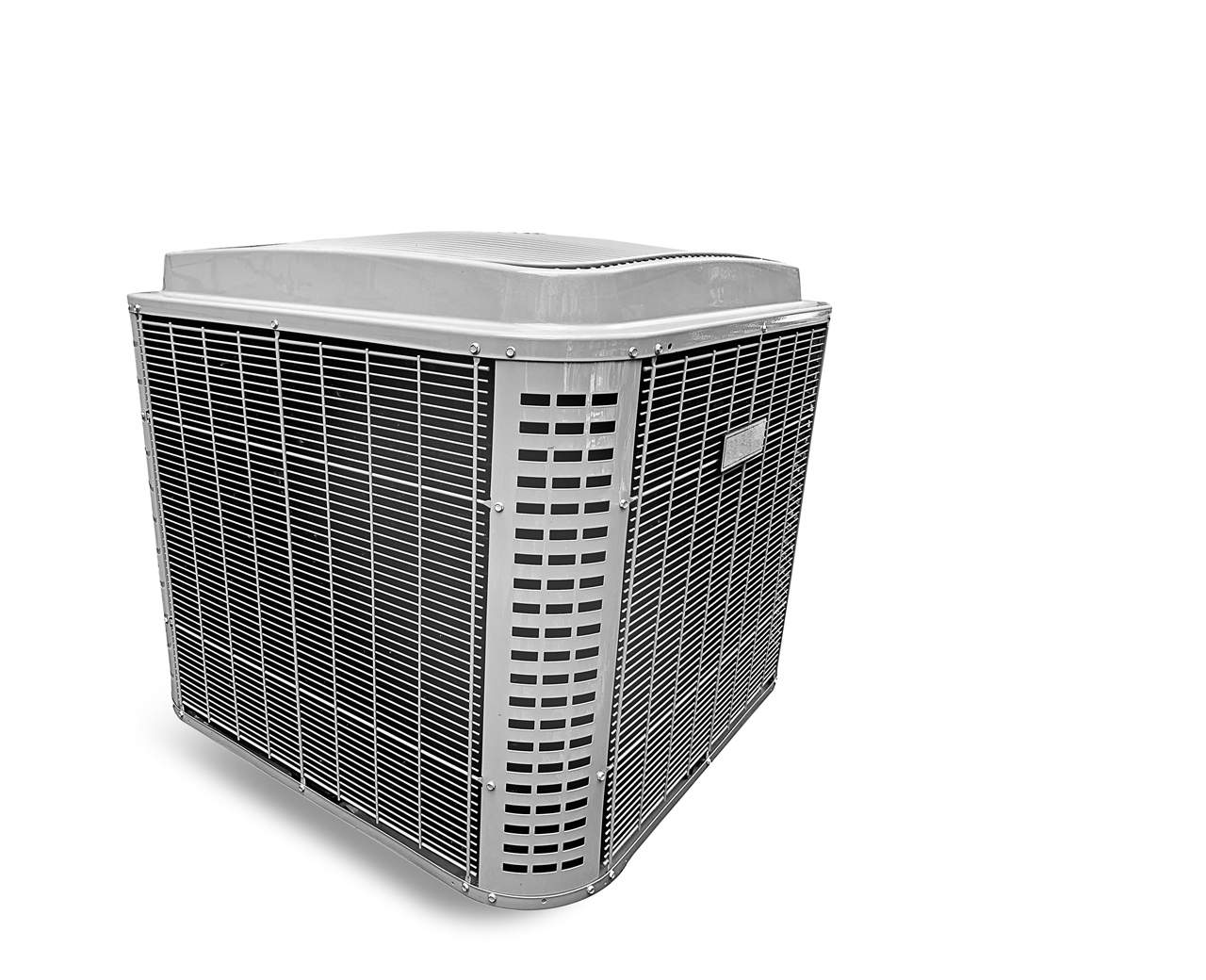

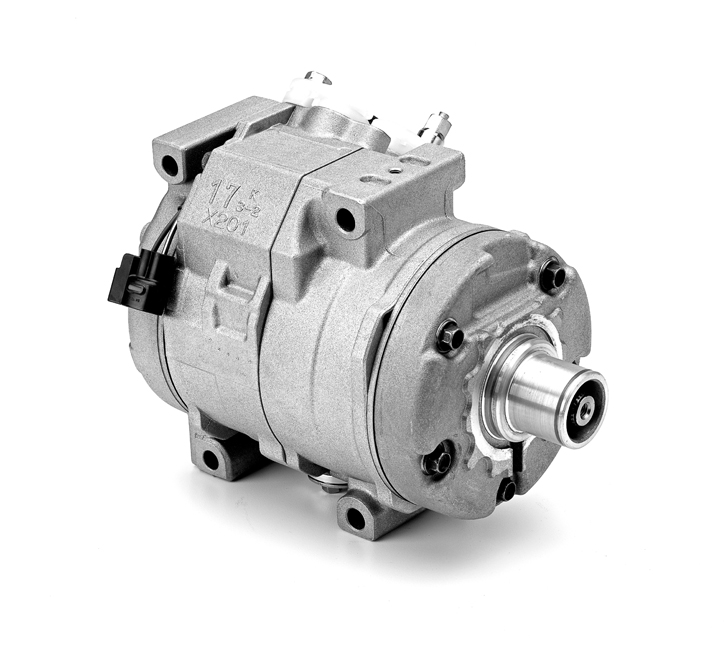

Fig. 01 - Loss Example

Mechanically Seized

A compressor supporting the air conditioning system mechanically seized due to lack of refrigerant. While a replacement compressor was being located, temporary fans were purchased.

The Causes

Mechanical breakdown is the second most common form of equipment failure. It accounts for 30% of all equipment breakdown claims yet results in a disproportionate 40% of loss in terms of total cost. This is due largely to the types of equipment involved. Factors contributing to mechanical breakdown:

- Lack of lubrication

- Misalignment

- Oil contamination

- Operator error

- Overspeed

- Vibration

Where it Happens

- Blowers

- Compressors

- Engines

- Fans

- Motors

- Pumps

How it Happens

- Bent components

- Broken parts

- Cracking of moving parts

- Fracturing of moving parts

- Seizing of moving parts

Prevention

Simple steps can be taken to minimize the risk or impact of potential loss caused by mechanical breakdown.

- Condition monitoring

- Contingency planning

- Proper lubrication

- Routine maintenance

- Trained operators

Partner Resources

For access to more tools, educational materials and information about equipment breakdown or our products and services, view our Partner Resources here.